Recent Post

Coffee Roasting

Steffen Sauer

Mar 29, 2021

Coffee roasting is the process through which green coffee beans transform into roasted beans, simply a dry heating without water and fat.

The heat not only caramelizes sugars and browns the coffee during the roasting process, it also catalyzes several other chemical and physical changes.

In fact, it is an easy formula:

There are a range of different styles and approaches to roasting. There are three basic types of heat: Conduction (contact heat) – Convection (hot air) – and Radiance (radiation) and thus different roasting machines. Regardless of the approach, the roaster evaluates the product’s progress based on an assortment of visual, smell, and temperature queues.

Beside the approach there are also different roasting levels. While lighter roast profiles tend to emphasize the unique characteristics of the coffee, darker roasts tend to emphasize more roast character. Each coffee has a specific roast profile.

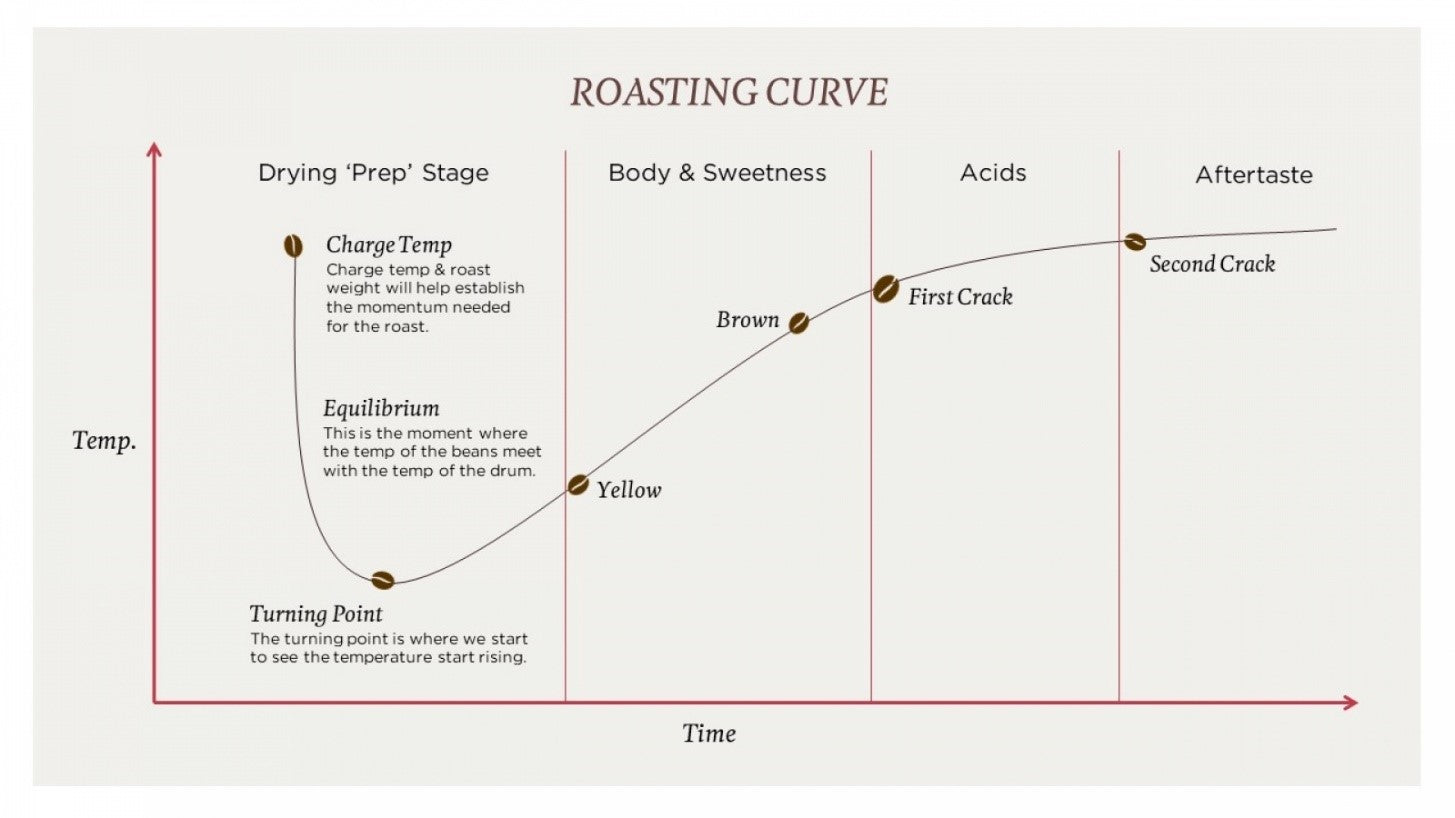

The roasting process itself has several stages you should know:

Drying the coffee beans

Green coffee contains up to 11 percent water, which must be distributed in the bean and evaporated before roasting. Therefore, in the first phase, the roaster is heated and filled with the beans until the water evaporates (at about 20-130 °C). This phase is important and must be done so that the whole bean is clear of the water, otherwise it will roast less inside and get an unpleasant, grassy taste.

The Maillard reaction

From about 130°C it starts with the roasting. Now the beans slowly turn yellow and change color to a beautiful caramel-like brown. Chemical processes take place in the bean, especially the so-called Maillard reaction (chemical reaction between amino acids and reducing sugars). The beans are significantly larger and the fine cuticles dissolve.

First Crack

In the bean, carbon dioxide and steam develop a pressure that bursts the bean. You can recognize this by cracking sounds. From now on, the beans are drinkable. With the degree of the roast, the roaster now decides on the right balance between acidity and bitterness.

Second Crack

If the roast is intended to be for a filter coffee, the roast probably finishes before the second crack. For espresso or dark roasts, the second crack is an important time. It is a second bursting of the bean - the pop sounds are a bit finer than the first crack. From now on, oils emerge from the beans. The acids and the characteristic flavors of the coffee are now only very weak but have more roasted and bitter notes.

Cooling the roasted beans

This is also an important step in roasting, as the beans need to be cooled down quickly to stop the reactions and stop the coffee from roasting.